menu'

-

project

Description of the project

-

objectives

Objectives of the project

-

WORKS

the work schedules

Description of the project

Objectives of the project

the work schedules

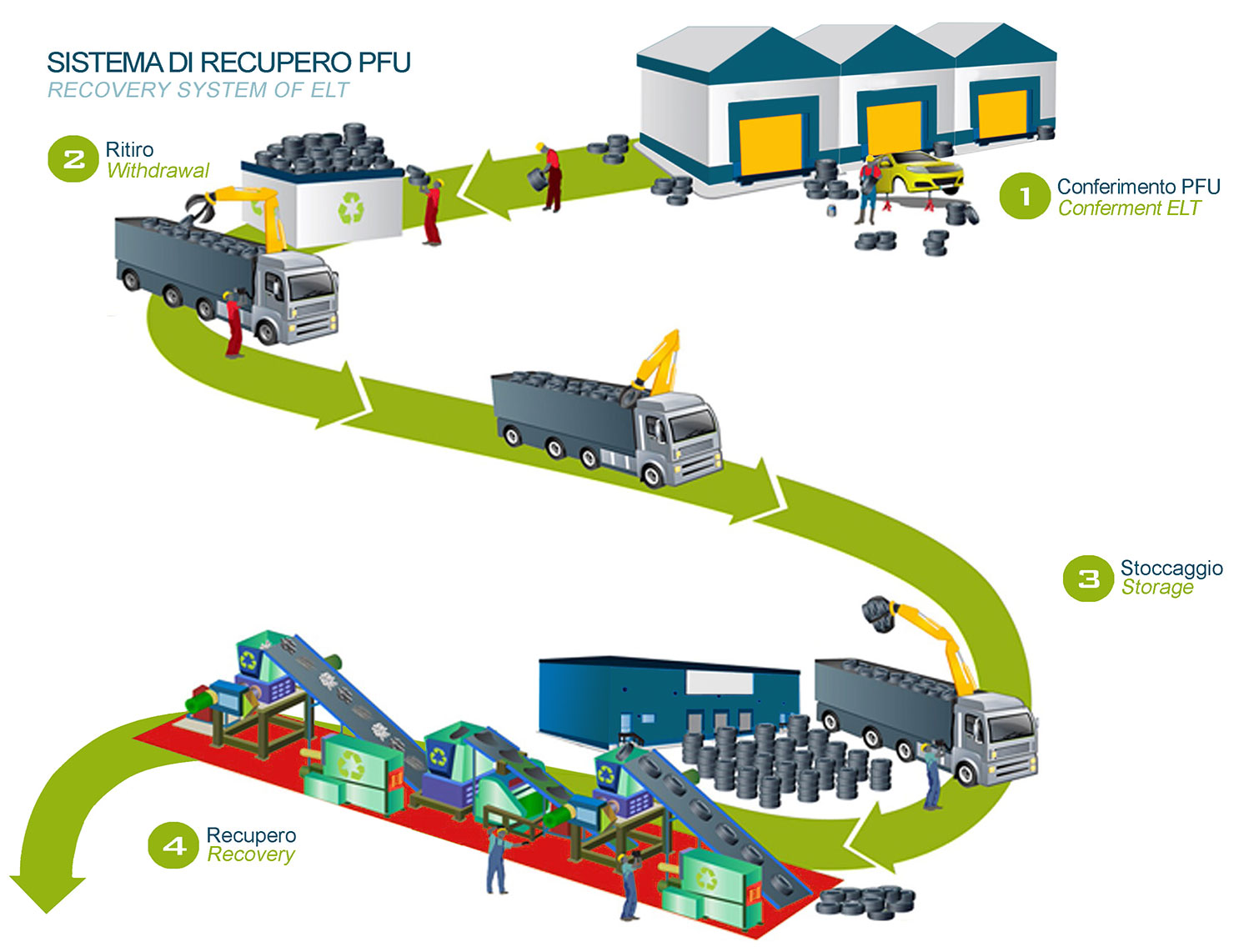

The project LIFE14ENV/IT/000160"Recycling of textile fibres from end-of-life tires for production of new asphalts and plastic compounds" leads to industrial application of textile fibres reuse from the recovery of ELTs (End-of-Life Tyres).

The ETL (End Tires Life) is a waste and in current legislation can follow two different courses of treatment: recovery of materials or energy recovery

From the ETLs recovery the following materials are obtained: elastomeric rubber granules, harmonic steel, and textile fiber mainly composed of nylon, rayon etc. The granules of rubber and harmonic steel are recycled in multiple applications. The textile fiber, which represents about 10% of the PFU (considering the weight), has not any use and ends up in landfills or incinerators.

The Project LIFE14 ENV/IT/000160 objectives are::

The project LIFE 14 ENV/IT/000160 is the natural evolution of R&D activity supported by the POR MARCHE FESR 2007-2013, called: RTP Process - Design and development of a new product resulting from the reuse of textile fibres waste from the shredding process of ELTs.

From this research two particularly interesting applications came to light:

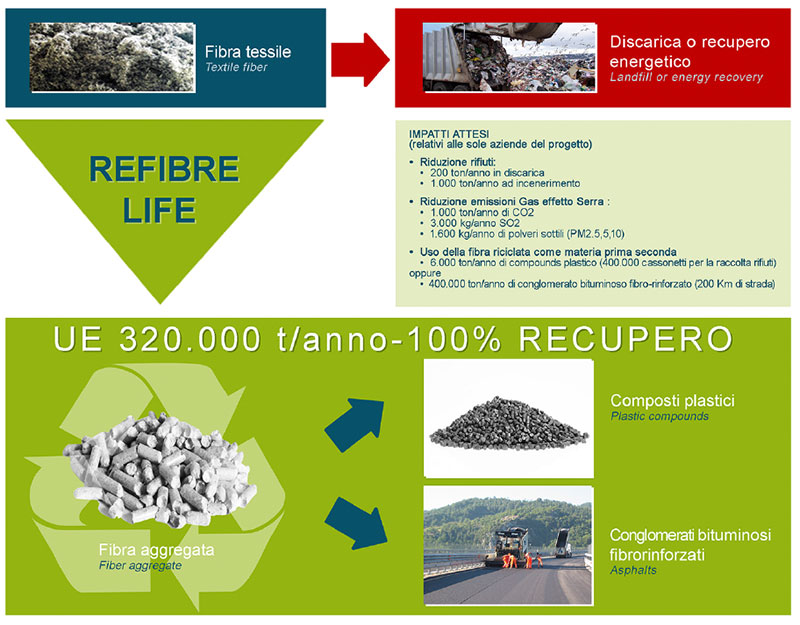

Textile fibres represent about 10% by weight of the end-of-life tyres (ELT) and every year, in Europe, about 320,000 tons of dirty fibrous material must be disposed as special waste. This results in negative impacts on the environment, in terms of GHG emissions and pollution, economic losses and public costs.

REFIBRE action aims to overcome the two main existing barriers limiting ELT fibre recycling, these are:

The ultimate goal of this project is 100% valorisation of the ELT fibre material and finally transform it into a useful secondary raw material according to a “circular economy” thinking. This can be done only through a new appropriate treatment of the fibre aimed at improving its quality and features in order to prepare it for reuse.

Therefore, the specific objectives of the REFIBRE project are:

The aim of the project LIFE14 ENV/IT/000160 is the industrialization of production on processes of asphalt and plastic compounds with added textile fibres by ELTs, in order to enter the market as a finished product.

The actions to be implemented are the following:

EXPECTED IMPACTS

REFIBRE contribute (impact only for the company)

alternative

This section lists the key stages of the project, divided into phases carried out and steps whose output is estimated for the next three months

The project phases are already done:

The steps involved for the next three months are: